Automotive Plastic Solutions

The automotive industry requires high-quality plastic components to enhance vehicle performance, safety, and aesthetics. They must be engineered to meet strict standards for durability, strength, and resistance to environmental factors such as heat and impact. Additionally, these components must integrate seamlessly into the vehicle’s overall design, ensuring both functionality and visual appeal.

At Seagate Plastics, we provide top-tier automotive plastic products tailored to clients’ specific requirements. Our manufacturing processes and cutting-edge technology enable us to deliver quality parts that meet or exceed industry standards. Moreover, our commitment to excellence ensures that every product leaving our facility is of the highest quality.

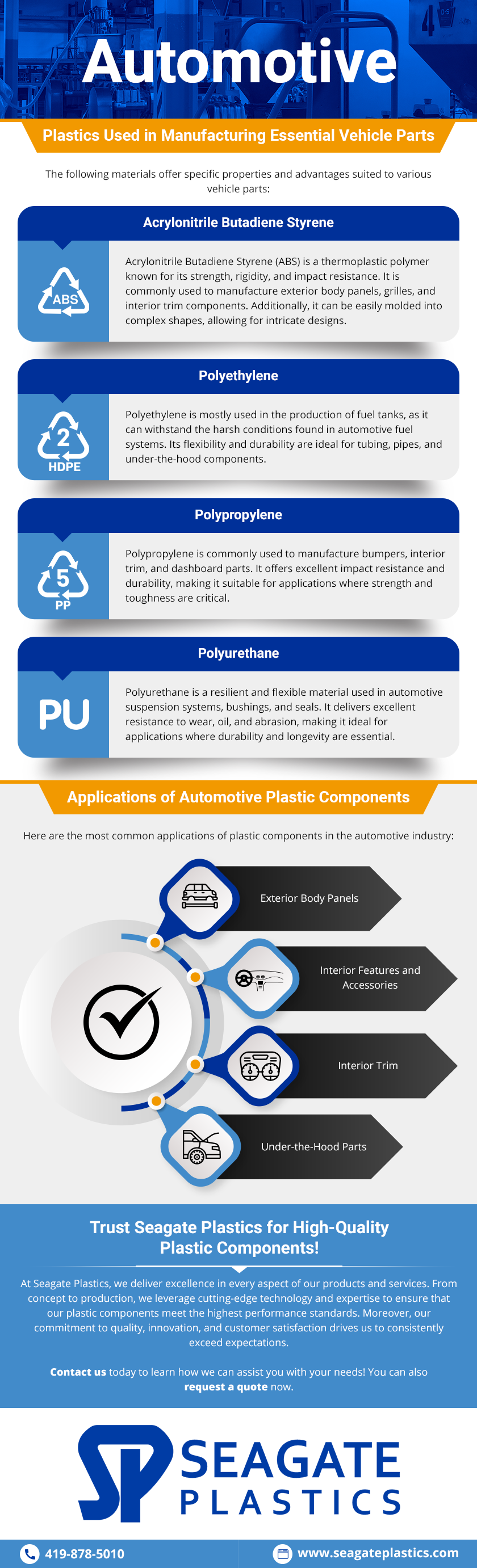

Plastics Used in Manufacturing Essential Vehicle Parts

The following materials offer specific properties and advantages suited to various vehicle parts:

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer known for its strength, rigidity, and impact resistance. It is commonly used to manufacture exterior body panels, grilles, and interior trim components. Additionally, it can be easily molded into complex shapes, allowing for intricate designs.

Polyethylene

Polyethylene is mostly used in the production of fuel tanks, as it can withstand the harsh conditions found in automotive fuel systems. Its flexibility and durability are ideal for tubing, pipes, and under-the-hood components.

Polypropylene

Polypropylene is commonly used to manufacture bumpers, interior trim, and dashboard parts. It offers excellent impact resistance and durability, making it suitable for applications where strength and toughness are critical.

Polyurethane

Polyurethane is a resilient and flexible material used in automotive suspension systems, bushings, and seals. It delivers excellent resistance to wear, oil, and abrasion, making it ideal for applications where durability and longevity are essential.

Applications of Automotive Plastic Components

Here are the most common applications of plastic components in the automotive industry:

Exterior Body Panels

Plastics are increasingly being utilized to manufacture exterior body panels, such as bumpers, fenders, hoods, and doors. These components benefit from plastics’ lightweight nature, which helps improve fuel efficiency and reduce vehicle weight.

Interior Features and Accessories

Plastics are used in various interior features and accessories, including seats, storage compartments, cup holders, and HVAC vents. They offer design versatility, allowing for the integration of functional features such as folding seats, adjustable storage bins, and modular console layouts.

Interior Trim

Automotive plastic components are extensively employed in interior trim applications, such as dashboard panels, door panels, center consoles, and trim pieces. They are lightweight, durable, and resistant to wear, contributing to overall interior comfort and longevity.

Under-the-Hood Parts

Various plastic components are found under the hood of vehicles, including engine covers, air intake manifolds, radiator tanks, and fluid reservoirs. Plastics in these applications must withstand high temperatures, chemical exposure, and mechanical stress.

Trust Seagate Plastics for High-Quality Plastic Components!

At Seagate Plastics, we deliver excellence in every aspect of our products and services. From concept to production, we leverage cutting-edge technology and expertise to ensure that our plastic components meet the highest performance standards. Moreover, our commitment to quality, innovation, and customer satisfaction drives us to consistently exceed expectations.

Contact us today to learn how we can assist you with your needs! You can also request a quote now.