In-House Project / Tool Design

A Beginner's Guide To Rigid Extrusion Design

Close attention to the design of an extrusion can pay immediate and permanent dividends.

For example:

- Simpler, less expensive tooling

- Reduced time from inception to full scale production

- Lower cost per foot of the extrusion

- Avoidance of quality issues during production

We hope that the following points help you towards these aims:

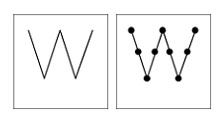

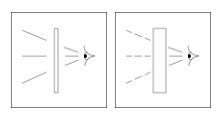

Even Wall Thickness

Wherever possible, profiles need an even wall thickness throughout. Without this, satisfactory production may eventually prove to be impossible, because large differences in thickness can:

- Cause the flow of material through the tool to be unequal, distorting the profile

- Cause cooling at different rates, which can result in bowing of the finished extrusion

![screen-14.23.08[06.06.2018] Guide](https://www.seagateplastics.com/wp-content/uploads/2021/10/screen-14.23.0806.06.2018.png)

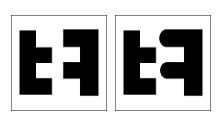

Avoid Detail In Hollow Sections

Many extrusions are hollow (e.g. tubes) and are made using vacuum forming tooling. If internal detail is required, it should be kept to a minimum as it is very difficult to calibrate or control during production.

Complex detail can be achieved, however, if the profile is opened up, no longer requiring the vacuum. Hollows within hollows should be avoided completely.

Mating Parts

Extrusions often need to fit mating parts, such as metal frames, a board, or end caps. Production is helped considerably if the mating parts are made available, to enable a "fit and function" test to take place. This saves time and helps to prove the drawings and tools.

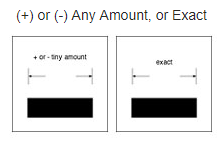

Length Tolerances

We recommend that, where you can, some tolerance is designed in to the required length of your extrusion. It can be difficult and expensive to cut a perfect length during production as thermoplastics expand and contract at different temperatures. Greater accuracy is possible if lengths are cut off-line, but this adds cost.

A typical length tolerance for PVC would be +/- .060 on a 72" length. Longer bar lengths are generally cut with a positive tolerance only, e.g. +.125" / -0".

Choosing Clear Materials

There are several plastics to choose from that give a clear finish. PVC is generally least expensive and is suitable for many applications, although it is not as clear as glass. Acrylic, HIPS, and PETG offer very good clarity, but with the latter, profiles need to be relatively simple. Polycarbonate is probably best for strength and rigidity.

If clarity is the over-riding requirement, the wall thickness should be kept to a minimum in any material.

Flexible Profiles

These are broadly subject to the same considerations as for rigids, other than for wall thickness.

Co-Extruded Profiles

Dual hardness plastic co-extrusions are manufactured by feeding different material through the same tooling. This enables rigid sections to be joined by a flexible hinge or a rigid profile to have flexible lips or flaps. It is also possible to co-extrude profiles with different colored parts (including clear).

We hope that the above introduction will help you with your design, but please do not hesitate to contact us to discuss you individual needs, and specific requirements.

To enable us to quote accurately, please provide the following information wherever possible:

- Sketch / Drawing or sample

- Color required - sample, RAL, Pantone or BS

- Material required

- Quantity required – both for samples and bulk order

- Length(s) required