Stock Plastic Extrusions

We have decades of design, engineering, and manufacturing experience to meet your needs. Our standard extruded profiles and tubes can also be fabricated for cost-effective custom plastic extrusions with quick turnaround.

Ready to get started? Contact us now to discuss your custom plastic needs with one of our pros.

The plastic extrusion process simplified:

Simply put, plastic extrusion is a high-volume manufacturing process in which raw plastic material is melted and formed into a continuous profile. The process creates two-dimensional shapes (length providing the third dimension) such as plastic tube extrusion, edging, moldings, FRP moldings, angles, and more in short sections or continuous lengths.

Extruded products can be utilized as-is, or they may be fabricated into more complex assemblies by punching, bending, forming, or other techniques. Using custom plastic extrusions can provide a quick, cost-effective solution to your custom fabrication and assembly needs.

Various appearance characteristics can be introduced into the custom profile extrusion with the addition of custom color concentrates. Plastic co-extrusion of dissimilar materials in one profile can increase the functionality of the custom profile extrusion.

Available Standard Profiles:

SeaGate Plastics manufactures and maintains a comprehensive catalog of extrusion shapes that meet routine requirements for structural support, edge protection, insulation, spacing, and decorative finishes. Available profiles include:

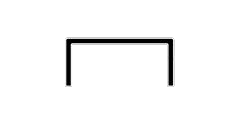

- U-Channels – often used for edge protection and framing

- C-Channels – suitable for sliding tracks and enclosures

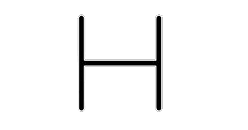

- H-Channels – for joining two flat panels

- FRP Molding - for joining two FRP panels

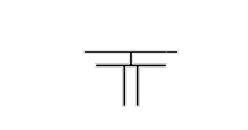

- T-Sections – used as dividers and structural supports

- Z-Bars and Angles – used in panel framing and reinforcing corners

- Flat Strips – useful for sealing, gasketing, or wear-resistant lining

- Welt Cords – typically applied in trim applications

- Dunnage Retainers – designed for shipping and packaging stability

- Connectors, Corners, Clips, and Hinges – functional parts for assembly and mobility

These profiles are manufactured in standard lengths and can often be cut to specific sizes as needed. Many are available in various colors, wall thicknesses, and levels of flexibility, depending on application needs.

Plastic Tube Extrusion Options:

SeaGate’s plastic tube extrusion capabilities include round, square, and rectangular tubing in a variety of dimensions. These are often used in packaging, insulation, and protective sleeves. Plastic tubes can serve as housings for wires and cables, supports in retail displays, or carriers in fluid and air handling systems.

Plastic tube extrusion is a key area of focus within the stock product range. These tubes are formed with consistent wall thicknesses and precise diameters to support dependable performance across different industries. Common materials used in these products include PVC, Polyethylene (HDPE/LDPE), Polycarbonate, and ABS.

Stock tubing is produced in both rigid and flexible options, with custom lengths and colors available for bulk orders. When standard tubing doesn't meet dimensional or performance needs, the engineering team can transition the project to custom production.

Material Selection:

SeaGate Plastics processes a wide range of thermoplastic materials to support stock production. These include:

- PVC (rigid and flexible) – known for chemical resistance and dimensional stability

- ABS – valued for impact resistance and durability - available in static dissipative

- Polyethylene (HDPE, LDPE, MDPE) – commonly used for lightweight, flexible extrusions, (HDPE available in static dissipative)

- Polypropylene – suited for structural and chemical handling applications

- Polystyrene (HIPS) – often used in lightweight framing and packaging

- Polycarbonate (PC) – a high-impact material ideal for glazing and protection

- PETG – used in display components and guards

- Thermoplastic Elastomers (TPE, TPR, TPU) – offer rubber-like properties in extrusion form

- Polyurethane – used where abrasion resistance is required

Some stock profiles are also produced with electrically conductive or static dissipative materials for use in electronic packaging and handling.

Plastic Co Extrusion Capabilities:

SeaGate Plastics uses plastic co-extrusion to produce stock and custom profiles that combine multiple materials or colors in a single part. Co-extrusion allows one layer to provide strength and rigidity, while another layer adds flexibility, grip, or sealing.

This process is used in many edge trims, seals, and dual-durometer products. For example, a co-extruded U-channel might include a rigid core and a soft gripping surface. While many co-extruded parts are developed through custom programs, several standard shapes that include co-extruded features are available for bulk purchase.

Plastic co-extrusion is particularly useful when combining functional needs without resorting to assembly. It supports applications in automotive interiors, retail point-of-purchase displays, and specialty packaging.

Stock vs Custom Plastic Extrusions:

Stock plastic extrusions provide a practical solution for repeat applications and proven designs. These products are ready for shipment or quick modification, helping projects move faster without the cost or lead time of new tooling.

Custom plastic extrusions, on the other hand, are produced for parts that require unique geometries, complex interaction with other parts, or specific branding. SeaGate supports both options. The team can help determine whether a stock profile meets the project’s performance goals or whether a custom tool should be developed.

For companies that begin with stock profiles but later require design refinements or integrations, SeaGate offers a smooth path to custom production.

Fabrication and Modification Options:

Stock extrusions can be modified and finished with a variety of fabrication services, allowing parts to ship closer to their final form. Available services include:

- Cut-to-length – parts can be trimmed to custom sizes before shipment

- Punching or Drilling – holes or slots can be added for fasteners or fitment

- Notching or Mitering – corners can be removed for clean angles

- Taping – adhesive backing can be applied during production

- Assembly – for multi-component extrusions or hardware integration

- Labeling and Packaging – available for retail or batch-tracked environments

These services allow companies to reduce labor and material handling on their own production lines.

Industries Served:

Stock plastic extrusions from SeaGate are used by manufacturers, fabricators, and distributors across many industries. These include:

- Construction – framing, sealing, trim, and insulation

- Automotive – edge protection, spacers, and tubing

- Retail Fixtures and Displays – signage frames, clips, and covers

- Warehousing and Material Handling – dunnage retainers and product guides

- Packaging – protective strips, sleeves, and containers

Because stock profiles are available in common shapes and materials, they often integrate easily into existing designs without modification.

Ready to Ship or Customize:

Stock extrusions from SeaGate Plastics are available for immediate shipment. With flexible minimums and support from experienced extrusion specialists, businesses can meet deadlines without compromising quality. If an exact fit isn't found in stock, custom plastic extrusions can be developed using the same manufacturing expertise and material options.

To request samples, pricing, or technical information on stock plastic extrusions, contact us today.