Plastic Injection Molding – Redesign

A Leader in Plastic Injection Molding

Our 26,000 sq. foot injection molding facility located in Addison, Michigan specializes in injection molding and related processes. Our machine capabilities range from 35 to 650 tons of clamp force. Processes such as insert molding and standard injection molding are available to meet your specialized molding needs. We can produce custom products in addition to our standard product line.

At SeaGate Plastics we utilize the newest technologies at our plastic injection molding facility. We utilize robotic parts handling and material reclaim process for more environmentally friendly processing.

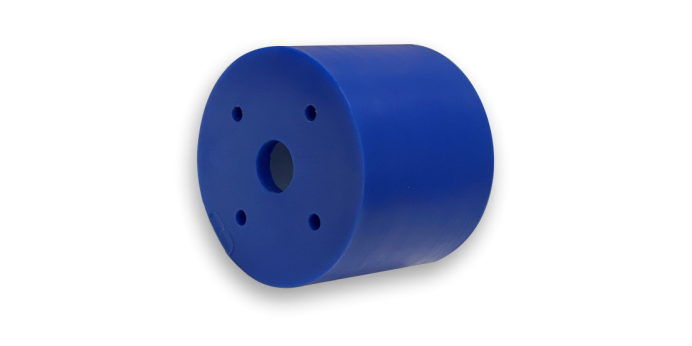

Our insert molding capability encapsulates metal or different plastic materials and other substrates in Thermoplastic to create more complex designs that combine rigid and flexible materials and can eliminate assembly and fasteners.

If you need a prototype on sample tooling, we can do that for you. We are able to make prototype parts quickly and cost effective for you. We also have established relationships with numerous experienced tooling sources which allow us to be more effective in making your parts correctly and on time.

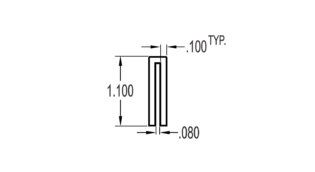

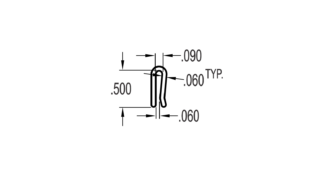

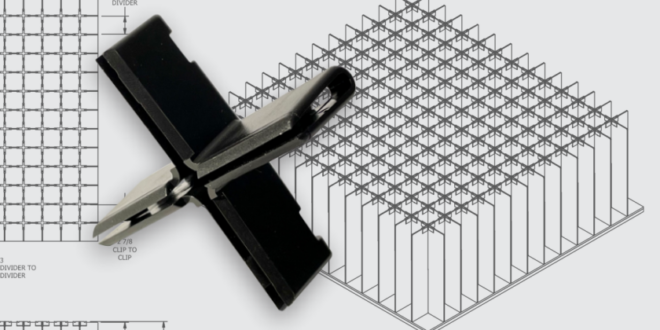

Injection Molded Dunnage

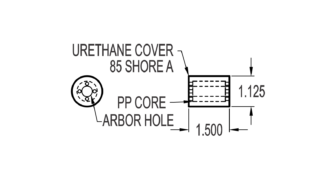

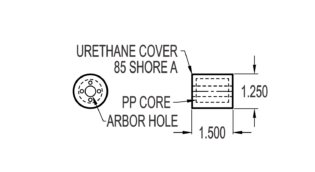

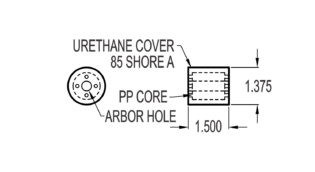

Urethane Glass Rollers

Corrugated Tote Components